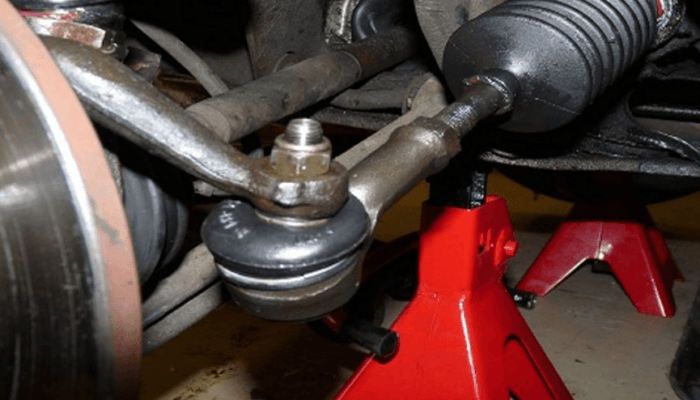

Males Baca – Tie rod and ball joint are essential parts of the steering and suspension system. Some vehicles are equipped with these components that need regular greasing, especially if they come with a grease nipple. Typically, this feature is found on larger vehicles like trucks and buses.

When these parts become worn out or loose, fixing the tie rod and ball joint becomes crucial to maintain stability and driving safety. This article will explain the symptoms of damage, and how to disassemble and repair tie rod and ball joint using simple tools.

Daftar Isi:

Signs of a Damaged Tie Rod and Ball Joint

Damage to the tie rod or ball joint will immediately impact your driving comfort and vehicle stability.

1. Steering Feels Loose or Shaky

A worn-out tie rod often causes the steering wheel to feel loose and unstable. There will be excessive play and less responsiveness in the steering.

2. Wheels Out of Alignment and Uneven Tire Wear

A damaged ball joint causes the wheels to tilt, leading to uneven tire wear. This makes it harder to control the vehicle, especially at moderate to high speeds.

3. Vibrations in the Steering Wheel

Issues with either of these components may also lead to noticeable vibrations in the steering wheel, even when driving on relatively smooth roads.

How to Disassemble Tie Rod and Ball Joint

Even if you don’t have a special tool like a puller, tie rod and ball joint can still be removed manually. However, be cautious to avoid damaging surrounding parts.

1. Use a Medium-Sized Hammer

A ball-peen hammer is commonly used in workshops to remove tie rods and ball joints without special tools. While this method is widely practiced, improper handling may lead to damage.

2. Disassembly Steps

- Remove the safety pin securing the tie rod and ball joint nut.

- Loosen and remove the locking nut on the component.

- Tap the tie rod and ball joint base (not directly on the part) with a medium hammer until it comes off.

- If the component is stuck, pry it gently or apply brake fluid to loosen rust.

How to Repair Damaged Tie Rod and Ball Joint

Once removed, the next step is to repair or replace the damaged tie rod and ball joint.

1. Check the Component’s Physical Condition

Inspect for signs of wear, cracks, or looseness in the tie rod or ball joint. If the damage is severe, it’s better to replace the part instead of making temporary fixes.

2. Clean and Lubricate if Still Usable

If only slightly worn and still usable, clean the internal parts and apply suitable grease to reduce friction.

3. Reinstall Neatly

Make sure all nuts and pins are tightened according to factory specifications. After reinstallation, perform a wheel alignment to ensure the wheels are straight and the vehicle is stable.

Conclusion

Repairing tie rods and ball joints can be done at home if you have the proper tools and basic knowledge. However, for the best and safest results, it is recommended to use specialized tools or seek help from a professional mechanic. Do not ignore signs of damage, as they can directly affect safety while driving.